|

|

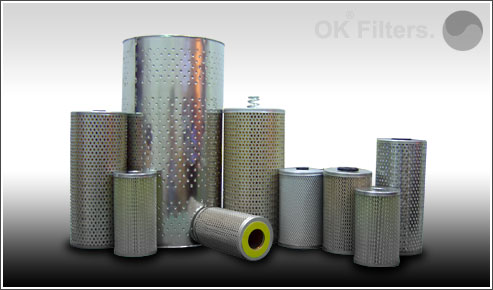

Oil Filters:

Our company

established since

1971, our Filters

has been at the

forefront of oil

filter technology

and performance for

passenger cars,

light trucks, heavy

trucks and buses,

and off-highway

vehicles. - meaning

we keep filtering

long after the

competition has

completely quit.

What the Oil Filter

Does...

You may take your

oil filter for

granted, but this

small, inexpensive

part of your

vehicle's

lubrication system

plays a vital role

in protecting the

engine from

premature wear. Each

moving part in the

engine and the

cylinder walls

requires clean oil

for proper

lubrication and

lasting life. The

oil filter cleans

the oil as it passes

through the filter

element or filtering

media. This prevents

abrasive

contaminants in the

engine lubrication

system from damaging

engine parts.

The better you

understand your

engine's lubrication

system, the more

you'll appreciate

the vital role your

oil filter plays.

When the engine is

running, oil enters

the oil pump through

a screened intake.

The screened intake

-- or oil pick-up --

is located in the

crankcase near the

bottom surface of

the oil pan. The oil

is drawn through the

screen intake and

forced by the oil

pump through the oil

filter.

Oil from the main

gallery is also fed

through vertical

passages to the

crankshaft main

bearings and through

the crankshaft to

the rod bearings.

Oil thrown from the

crankshaft, or

sprayed from the

connecting rods,

lubricates the

pistons and cylinder

walls.

In a typical

full-flow type oil

filter, the oil

flows into an inlet

passage and then

through the

filtering element.

After flowing

through the filter

element, the

filtered or "clean"

oil passes directly

to the main oil

gallery. In a

partial-flow type

filter, the oil

returns directly to

the oil pan.

Oil Filter Media

The media is the

filtering material

in the oil filter

element. It

essentially

determines the

efficiency,

performance and

useful life of the

oil filter.

There are two basic

types of filter

media: the "paper"

media and the

"depth" type media.

The primary features

of the filter

elements are:

Particle size

retention

(filtration

efficiency)

Particle size

retention is the

measure of the

degree to which the

filter can retain

particles of various

sizes. Our filters

has developed

optimum particle

size retention

quality in filter

media by

sophisticated

laboratory tests.

Our filters media in

the automotive

full-flow oil filter

is able to trap and

hold essentially all

the contaminant

particles larger

than 25 microns. (A

human hair measures

approximately 70

microns in diameter.

An object that is 1

micron in size is

.000039 inches in

diameter.) Our

filters also capture

a high percentage of

even smaller

particles.

Dirt-holding

capacity

Dirt-holding

capacity is the

amount of

contaminant that can

be removed and held

by the filter until

the filter ceases to

function. The

capacity of our

filters is

significantly larger

than the minimum

requirements to

efficiently filter

all the oil during

the oil and filter

change periods as

specified by vehicle

manufacturers.

Resistance to oil

flow

Our filters

full-flow oil

filters for

automotive

applications use

arch-pleated,

prescription-blended

media. When new, the

media with a

maximized number of

pleats has less than

2 psi pressure drop

when filtering oil

at a rate of 4

g.p.m. at normal

operating

temperature. This

low initial

restriction to oil

flow protects the

vital engine parts

more effectively.

Parts of an Oil

Filter

Gasket -

provides

exterior seal

between the

filter and

engine at the

engine mounting

surface.

Mounting Plate -

prevents

deflection

(movement) at

the gasket

sealing surface.

Heavy gage steel

plate provides

for threaded

attachment to

the engine.

Inner Element

Support -

provides inner

element

stabilization

and a positive

seal between the

inner element

and the mounting

plate to prevent

the bypass of

unfiltered oil.

Upper End Cap -

retains element

end sealant and

filter media,

provides an

outlet for clean

oil, and

provides

structural

rigidity to the

pleated media.

Lower End Cap -

retains element

end sealant and

filter media.

Arch-pleated,

Prescription-blended

Filter Media -

provides a more

than adequate

filter area. The

element has a

controlled

porosity blended

media to assure

complete

filtration of

the oil.

Spiral-wound

Center Tube -

provides

internal element

support. The

spiral design

greatly reduces

initial flow

restriction when

compared to

other designs.

Coiled Spring -

ensures a

constant load on

the inner

element to

maintain the

seal between the

upper element

end cap, the

inner element

support, and the

mounting plate

even during

pressure surge

situations.

- Filter

Canister -

encloses the

assembly with a

mechanically-locked

double seam. The

canister

provides

"flutes" at the

closed end for

ease of removal

with an oil

filter wrench.

- Silicone

Anti-Drainback

Valve - Stays

flexible in

extreme

temperatures,

improves oil

flow and keeps

oil in filter to

prevent engine

destroying dry

starts. Also

provides lasting

protection to

meet new vehicle

manufacturers

longer

recommended oil

change

schedules.

Nitrile valves

can harden and

become

ineffective over

time.

Some of our

filters full-flow

filters include

anti-drainback

and/or filter

by-pass valves.

These types of

filters are

identical to

full-flow filters,

except that a

by-pass valve

replaces the inner

element support and

an anti-drainback

valve has been

added. The

Anti-Drainback Valve

prevents oil from

draining out of the

filter inlet holes

when the engine is

shut off. It also

provides seal

between clean and

dirty oil at the

upper end cap. This

is necessary in

applications where

the oil filter is

mounted in a

horizontal or

inverted position.

The Filter By-Pass

Valve

If a Our filters

full-flow filter

becomes "clogged",

or excessively

restrictive to oil

flow, the filter

by-pass valve

ensures continued

engine lubrication

by allowing the oil

to by-pass the

filter. Some vehicle

manufacturers have

the by-pass valve

built into the oil

filter mounting unit

(located on the

engine).

Other vehicle

manufacturers

require full-flow

filters have the

by-pass valve built

into the filter

itself. All Our

filters oil filter

types recommended

for these particular

applications include

the :

1- by-pass valve

assembly in the

filter.

2- By-pass Valve

Assembly --

spring loaded

valve assembly

that allows oil

to

3- By-pass the

element under

high-differential

pressure

conditions such

as cold oil

and/or

excessively

contaminated

media. This

allows

lubrication of

the engine, but

without

full-flow

filtration.

|

|